[ad_1]

TULSA, Okla. â $ ” Elements and labor scarcities. Postponed distribution of brand-new aircrafts from Boeing and Airplane. An engine recall. Early restore providers. It is all accumulating, and airplane engine look across the globe are overflowing.Â

As vacationers boarded airplanes in doc numbers this summertime, airline firm execs waited anxiously for restore providers and overhauls of their engines.

The fixing and overhaul of engines has really swelled from a $31 billion service previous to the pandemic to $58 billion this yr, in keeping with Alton Aeronautics Working As A Advisor. It is a golden goose for engine producers like GE Aerospace and the quite a few smaller sized consultants that answer GE engines, and others made by Pratt & & Whitney and Rolls-Royce.

American Airways‘ service is to do much more of the job itself.

” We merely have one shopper which’s American Airways doing our job,” American’s principal operating police officer, David Seymour, claimed. “We will handle our very personal destiny as a result of location.”

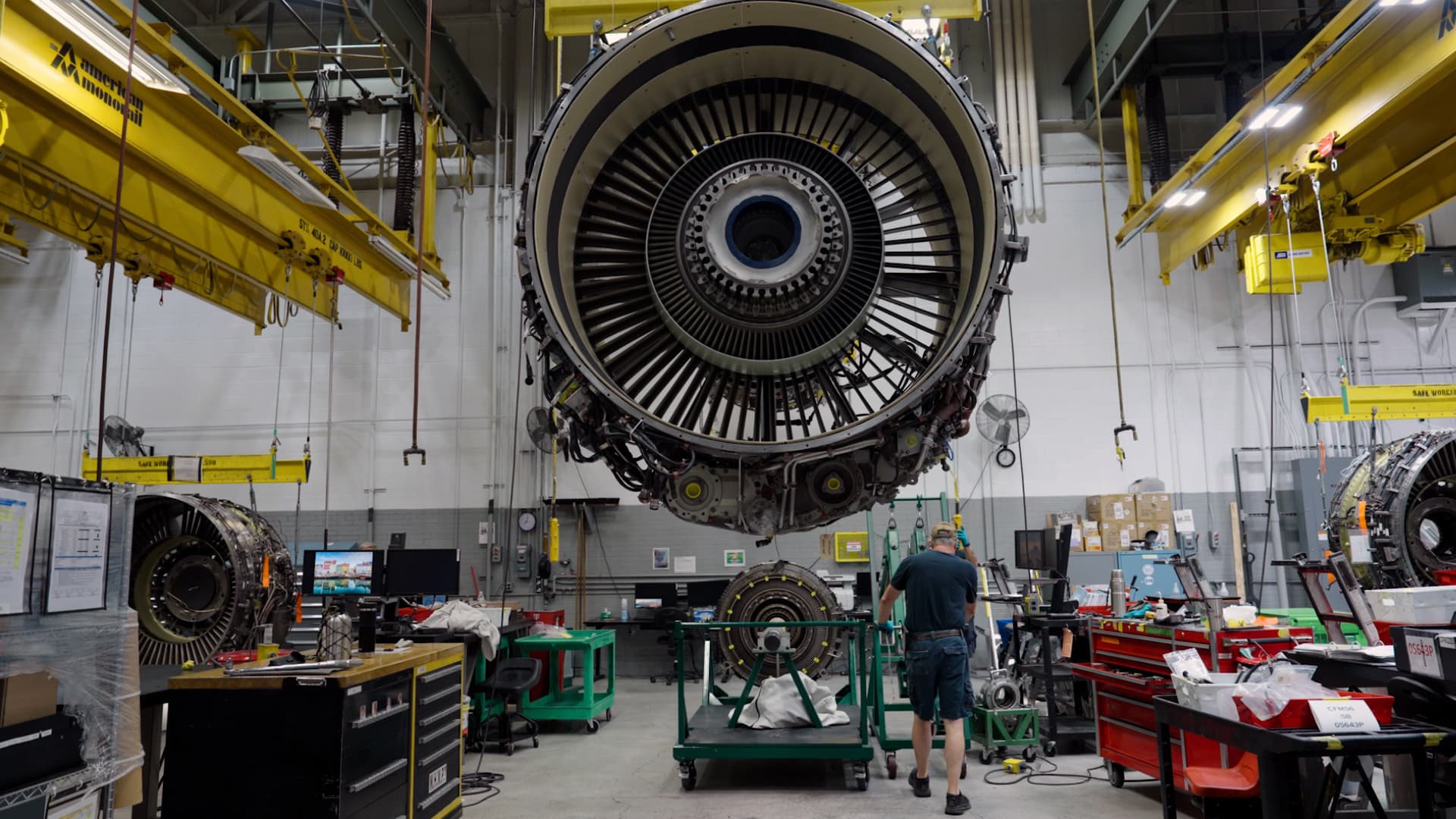

American Airways workers do repairs on CFM-56 engine in Tulsa, Oklahoma

Erin Black|CNBC

At its busy engine patronize the airline firm’s 3.3 million-square-foot repairs middle at Tulsa Worldwide Flight terminal, the largest such space on the planet, American will get on monitor to boost its overhauls about 60% from 2023 to better than 16 engines a month this yr. That is up from 5 a month in 2022. It is included some 200 work there, too additional instruments like cranes to hold the 2-ton engines all through overhauls.

The job concentrates on CFM56 engines, made by a joint endeavor of GE and France’s Safran. They energy American’s older Boeing 737 workhorse jetliners and several other Airplane A320s. These narrow-body aircrafts comprise most of American’s mainline fleet of better than 960 airplane, in keeping with a yearly agency protections declaring.

” I can receive these engines revamped and with the shop in a lot lower than 60 days versus [outside] shops these days [are] 120 to 150 days, in lots of instances north of 200 days,” COO Seymour claimed.

Site visitors jams abound

American Airways workers revamp an engine at a storage in Tulsa, Okla.

Leslie Josephs/CNBC

A lot of the visitors jam in engine restore providers comes from the sector’s rocky emergence from the pandemic, when companies shed thousands of skilled workers. Airlines that delayed maintenance during the travel slump then raced to get airplanes into shape to fly when demand snapped back, but faced worker and experience shortages and shortfalls of key items from engine components to aircraft seats.

Meanwhile, Airbus and Boeing are behind on deliveries of new, more fuel-efficient airplanes, forcing carriers, including American, to hold on to older jetliners longer than they planned.

Airbus this summer reduced its aircraft delivery forecast and announced cost cuts as it grapples with supply chain issues and late-arriving landing gear and engines.

“I would also call it the surprise factor for 2024,” Airbus CFO Thomas Toepfer said on a July 30 earnings call.

In addition to supply chain issues, Boeing aircraft have been delayed as the company navigates a safety crisis after a door panel blew out from one of its 737 Max planes midair at the start of the year.

With many engines needing overhauls about every 7,000 flights, keeping older airplanes longer means more routine maintenance and revamps, adding to demand when they’re due to come into the shop. Those weekslong overhauls are exhaustive: They can cost $5 million apiece and can go for double that for wide-body airplanes, according to Kevin Michaels, a managing director at AeroDynamic Advisory.

At American’s shop in Tulsa, workers remove hundreds of parts, replacing life-limited components and cleaning and inspecting others, which includes spraying them down with a a fluorescent penetrant so defects can be seen under a black light.

An American Airlines worker sprays florescent penetrant on engine components to check for defects at a hangar in Tulsa, Oklahoma.

Leslie Josephs/CNBC

But key parts are hard to find and they must be flawless. Plus, they’re costly. The dozens of engine compressor blades can go for $30,000 a pop.

On top of that, some newer engines â which run hotter, take in more air and burn less fuel than older types â are coming into engine shops earlier than expected, frustrating airline CEOs.

“There’s no business which can digest not using the key assets to generate revenue,” said AirBaltic CEO Martin Gauss.

The Riga, Latvia-based carrier, an Airbus A220 customer, had to lease planes in recent years to make up for its grounded jets.

“Unfortunately, passengers are not happy when they can’t fly on new aircraft,” he said. “It is an issue which will be over one day. We thought it would be over by now. I would give it another two years and then we are through it.”

There’s another problem that’s clogging up engine shops: A Pratt & Whitney engine recall of some of its narrow-body engines. In light of the ongoing issues, some low-cost airlines, including JetBlue Airways and Spirit Airlines, are deferring new jet deliveries to try to save money.

“It’s kind of a wicked brew that’s had a significant impact on the engine supply chain,” said AeroDynamic Advisory’s Michaels.

Windfall for engine makers

American Airlines worker looks inside engine at maintenance shop in Tulsa, Oklahoma.

Erin Black | CNBC

The high demand for engine overhauls has been lucrative for engine suppliers, which make billions from maintaining engines they sell with new airplanes.

GE Aerospace brought in $11.7 billion from engine maintenance, repairs and overhaul in the first half of 2024, making up 65% of its revenue.

“When it comes to engines, it’s a razor-razor blade business,” said Michaels, describing how buying shavers in a drug store can mean repeat business for replacement blades for years. “So the money is made in the aftermarket on the engine business.”

GE Aerospace, which became an independent company in April, said in July that it will invest $1 billion to replace its engine go searching all around the world the next 5 years.

Obtained spares?

For a number of airline corporations, there aren’t a number of decisions to expensive engine overhauls with want rising for substitute engines, particularly if the supplier has one type of airplane or a model that simply has one vendor.

An plane engine at American Airways’ examination cell in Tulsa, Oklahoma.

Leslie Josephs/CNBC

Rental costs for engines that evaluate with each previous and brand-new airplanes have really elevated. For example, a CFM56 engine made use of on the Boeing 737-800 was choosing $96,000 a month up from $78,000 in 2017, in keeping with air journey data firm IBA.

Each Pratt & & Whitney and CFM engines that energy the newer Airplane A320neo aircrafts, on the similar time, have really logged lease costs of $127,000 month-to-month, up from $80,000 and $85,000, particularly, in 2017, IBA claimed.

Leasing corporations like AerCap and Avolon have really been nabbing up additional engines because of the excessive want.

It’s nonetheless onerous to enter an engine retailer, nonetheless.

Delta Air Lines, like American, overhauls, repairs and maintains its own engines. It also does work for other airlines, but CEO Ed Bastian says the shop is full.

“If you’re not on an existing contract, you’re not getting in,” he said in an interview in July. “It would be easier to get into a Taylor Swift concert.”

[ad_2]

Source link .